Advanced Planning & Scheduling Software

Advanced Planning & Scheduling software plans and schedules production based on capacity, materials, and labour, adapting readily to changes in a range of environments.

- Make to order

- Make to stock

- Constrained capacity

- Component assembly

- Frequent or unpredictable schedule changes

- Competing priorities

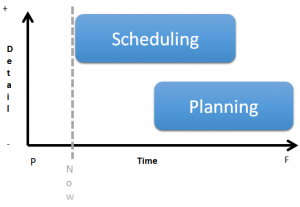

An understanding of the difference between Planning & Scheduling is crucial to selecting the right solutions.

Planning vs Scheduling, what’s the difference?

Planning is looking out longer term, aggregating your forecast, aggregating your supply and putting them into slices of time. The task to be done is that if you see in any one of those slices of time that your forecast exceeds your ability to supply then you need to make either make some product early and inventory it or shift production to another facility.

Scheduling then is taking actual sales orders and putting the processes in sequence. Scheduling needs to honor all the constraints. Scheduling needs to be practical. In essence, you are creating a work to list that can be released to the shop floor.

We have extensive experience with a range of manufacturing software systems such as APS, MES, MPS, and MRP, and can assist you in implementing the right solution to solve your production challenges.

Contact Us